-

Products

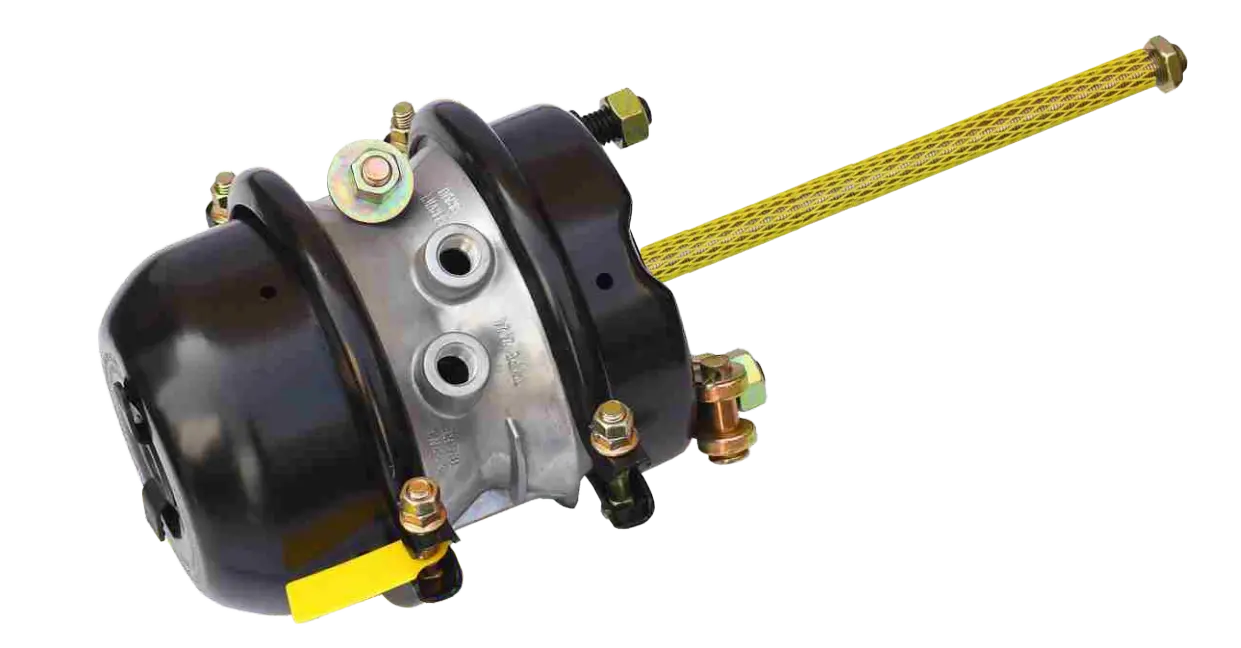

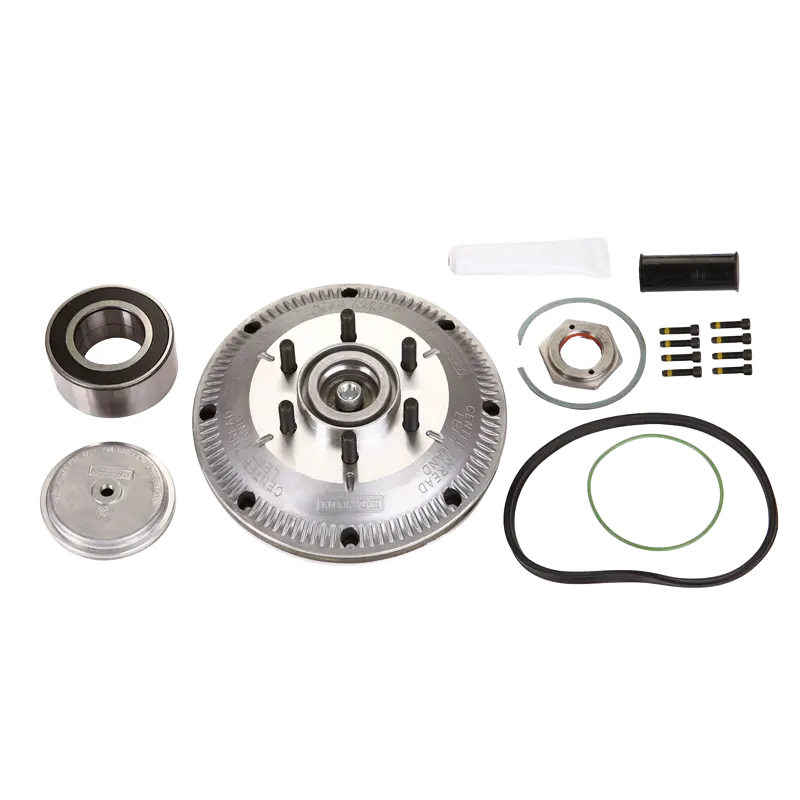

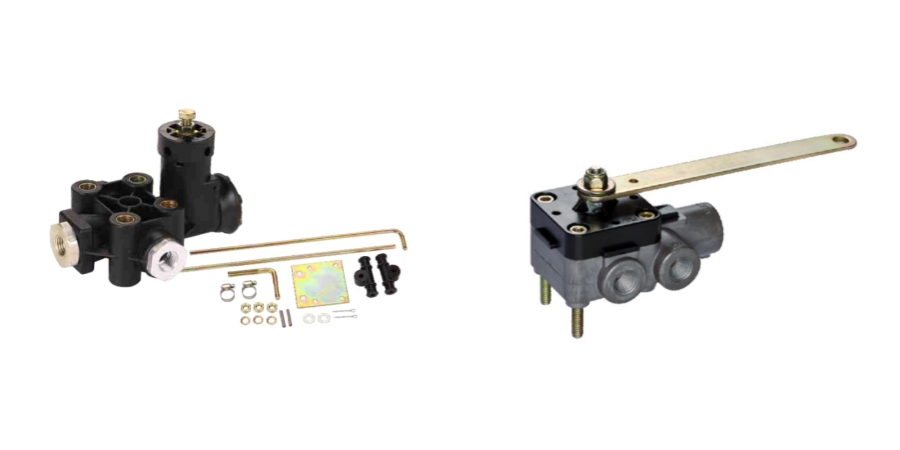

Air Dryer (17)AD-HF Air Dryer AD-9SI Air Dryer AD-9 Air Dryer AD-IP Air Dryer AD-IS Air Dryer Air Brake Dryer System Saver 1800 Air Dryer Meritor-Wabco SS-1200 Plus Air Dryer System Saver 1200 Air Dryer ADSP Air Dryer SKF Turbo-2000 Air Dryer Haldex Dryest Air Dryer Haldex ModulAir Air Dryer Haldex PURest Air Dryer Wabco Air Dryer 4324101020 Knorr-Bremse Air Dryer Duradrain ValveBrake Valve (20)D-2 Governor MV-3 Control Valve MIDLAND Control Valve PP-DC Control Valve Control Valve Foot Brake Valve Manual Drain Valve Relay Valve ABS System Relay Emergency Valve Tractor Protection Valve Air Manifold Quick Release Valve Stop Light Switch Solenoid Control Valve Spring Brake Control Valve Pressure Protection Valve Safety Valve Check Valve Alcohol EvaporatorAir Compressor (32)TKL3972531 Air Compressor TKL3969104 Air Compressor TKL3104324 Air Compressor TKL3968085 Air Compressor TKL3971519 Air Compressor TKL4936049 Air Compressor TKL4933782 Air Compressor TKL3411777 Air Compressor TKL4946294 Air Compressor TKL4946293 Air Compressor TKL3103413 Air Compressor TKL3696936 Air Compressor TKL107506X Air Compressor TKL4P0676 Air Compressor TKL109430 Air Compressor TKL1W6473 Air Compressor TKL1W6753 Air Compressor TKL1117994 Air Compressor TKL107508X Air Compressor TKL1W7146 Air Compressor TKL504290730 Air Compressor TKLLP4857 Air Compressor TKL-CIVRN-1340T Air Compressor TKLLK3994 Air Compressor TKLACX67BAG Air Compressor TKL41211219 Air Compressor TKL-CIV-1314T Air Compressor TKLACX67AAG Air Compressor TKL-CMB-5201T Air Compressor TKL-CV-2335T Air Compressor TKLEL1300 Air Compressor TKL-CH-DF-8906T Air Compressor Cylinder HeadAir Spring (20)TKL9675 Air Spring TKL8774 Air Spring TKL8050 Air Spring TKL9371 Air Spring TKL8091 Air Spring TKL7140 Air Spring TKL9270 Air Spring TKL7795 Air Spring TKL7116 Air Spring TKL7059 Air Spring TKL7046 Air Spring TKL7064 Air Spring TKL7108 Air Spring TKL7136 Air Spring TKL9122 Air Spring TKL9121 Air Spring TKL9781 Air Spring TKL8749 Air Spring TKL7206 Air Spring TKL9541 Air Spring

- Company

- News

- Support

- Contact

0

English

English Español

Español