Technical Background

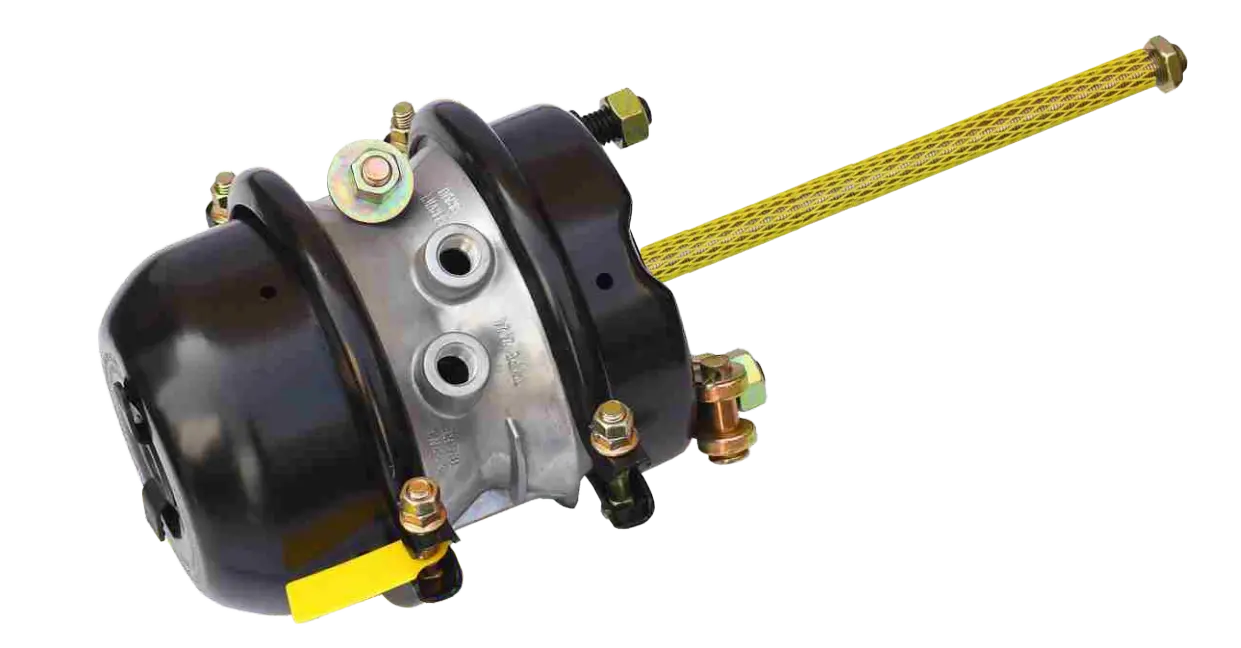

The spring brake chamber is a core actuator in automotive braking systems, converting compressed air energy and spring force into the mechanical thrust required for vehicle braking. The interior of a dual-diaphragm spring brake chamber is divided by the center body and rubber diaphragms into two cavities: the service brake chamber, connected to the relay valve outlet and controlled by the brake pedal, and the parking brake chamber, controlled by the hand brake valve.

In current market-available dual-diaphragm spring brake chambers, the rear cover typically contains four to six breather holes. During long-term use, external sewage, mud, and dust can enter the chamber through these breather holes, where they may accumulate and remain trapped. This leads to accelerated corrosion of the metal housing and internal components, including several key parts such as the pressure plate, parking spring, and rubber diaphragms. As a result, the service life and stability of the spring brake chamber are significantly affected.

This design provides an internal breathing component for an external truck spring brake chamber. Without altering the existing production process of dual-diaphragm spring brake chambers, it eliminates the breather holes on the rear cover and directly installs this component. The solution prevents external sewage, mud, and dust from entering the chamber, ensures a clean operating environment for critical internal components, and thereby improves the product's service life and operational stability, ensuring stable brake force output for the vehicle.

Summary of the Invention

The invention provides an internal breathing component for an external spring brake chamber.

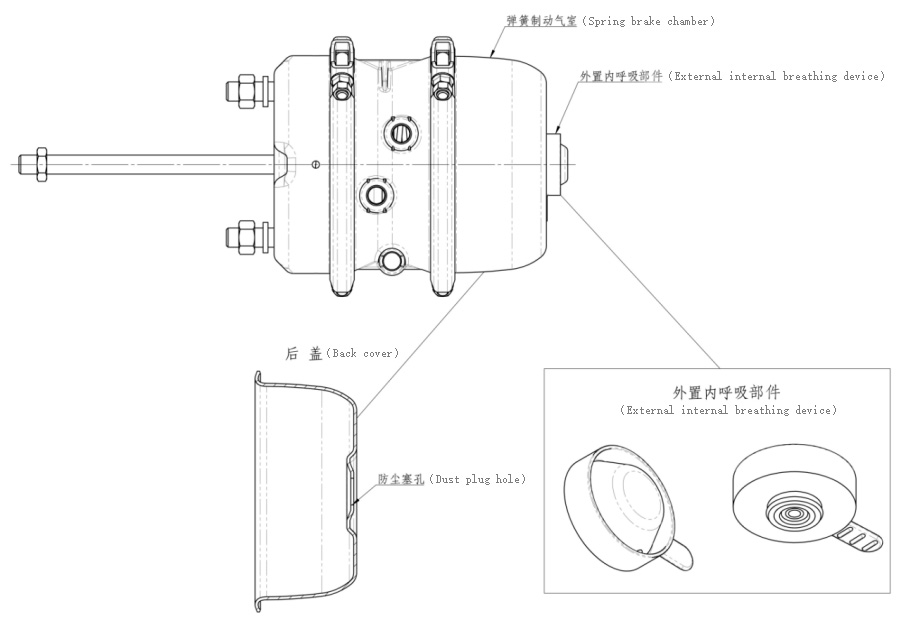

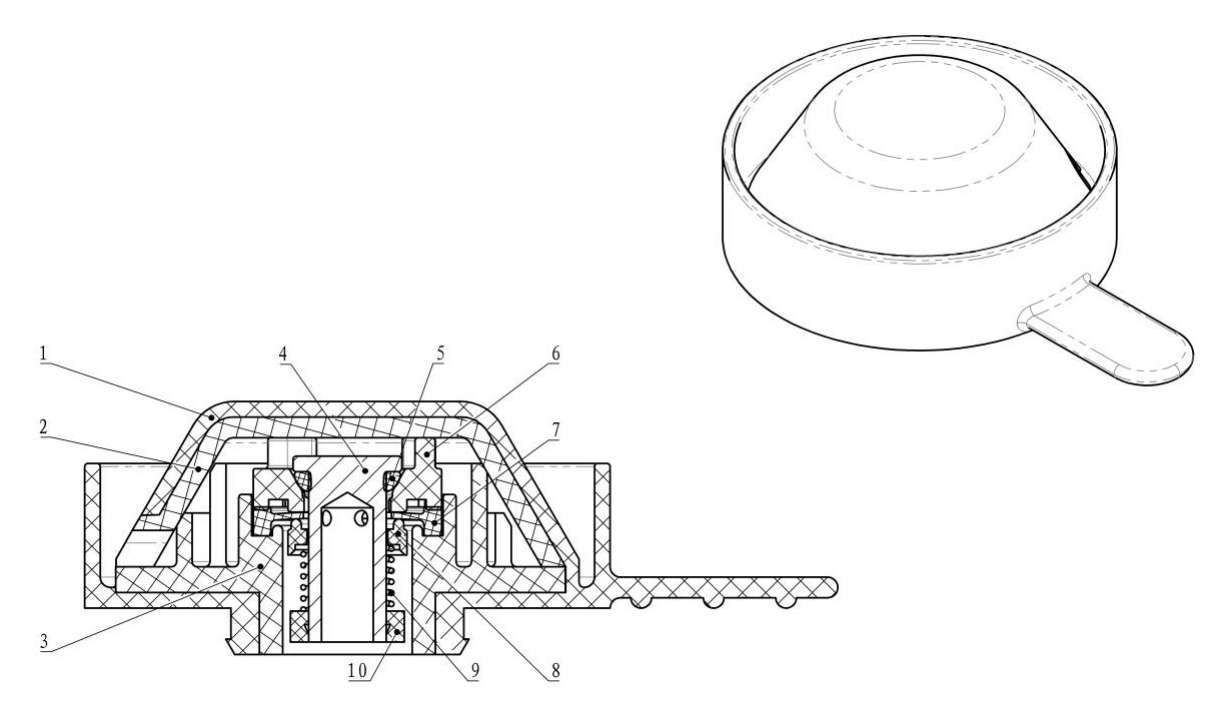

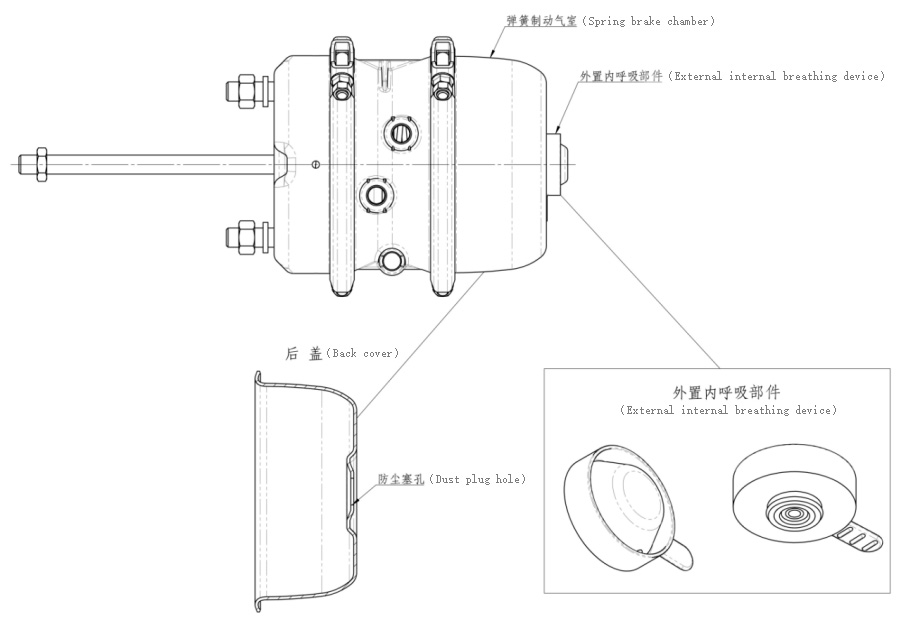

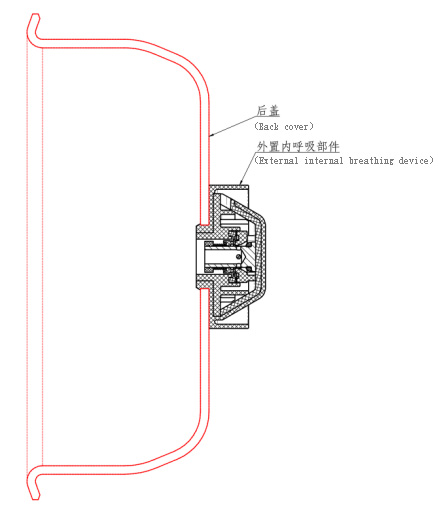

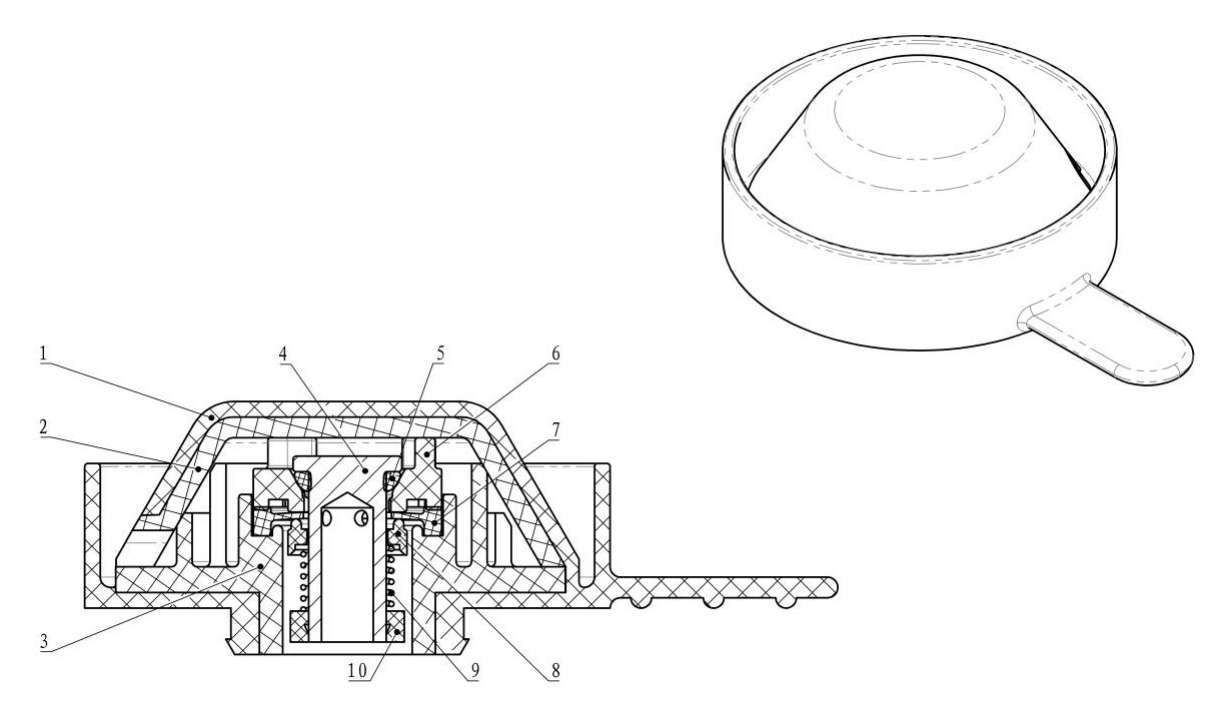

Figure (a) shows a schematic of a dual-diaphragm spring brake chamber equipped with the external internal breathing component, and Figure (c) shows a schematic of the breathing component itself. The invention integrates the cover, upper cap, base, valve core, valve seat, valve spring, and other parts into a compact and simple assembly that is easy to install together with the spring brake chamber.

In this invention:

Assembly of the valve core subassembly:

First, the annular sealing ring (5) is fitted onto the valve core (9). Then, with the larger end of the valve core facing downward, it is positioned in the tooling fixture. Following the sequence shown in Figure (c), the valve seat (6), diaphragm (7), valve (8), spring (9), and valve core seat (10) are placed onto the valve core. The tooling fixture is activated so that the barbs on the valve core securely lock the valve core seat (10) in place. The assembled components are collectively referred to as the valve core subassembly.

Assembly of the inner housing:

The valve core subassembly is placed onto the base (3). The six small lugs on the upper cap (2) are aligned with the six small holes on the base (3), and the two parts are snapped together, forming the internal core structure, referred to as the inner housing assembly.

Injection molding of the outer cover:

The inner housing assembly is placed into the mold. Through an injection-molding process, the cover (1) shown in Figure (c) is formed around and encapsulates the inner housing assembly.

Following the above process steps, a complete internal breathing component is produced.

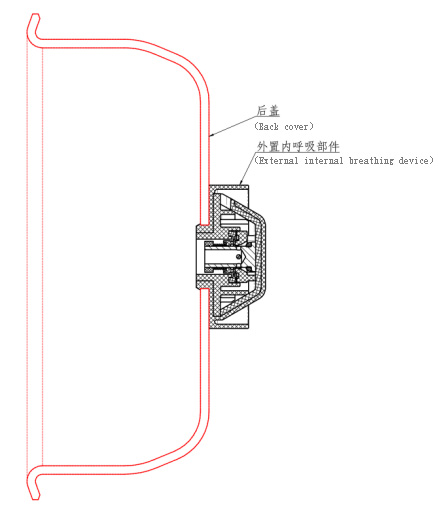

Figure (a) Spring Brake Chamber with External Internal Breathing Structure

Figure (b) Installation Location of the External Internal Breathing Component

1 – Cover, 2 – Upper Cap, 3 – Base, 4 – Valve Core, 5 – Annular Sealing Ring, 6 – Valve Seat, 7 – Diaphragm, 8 – Valve, 9 – Valve Spring, 10 – Valve Core Seat

Figure (c) Schematic of the External Internal Breathing Structure

Operating Conditions

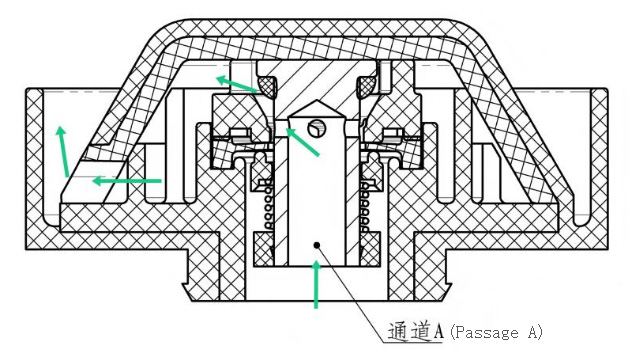

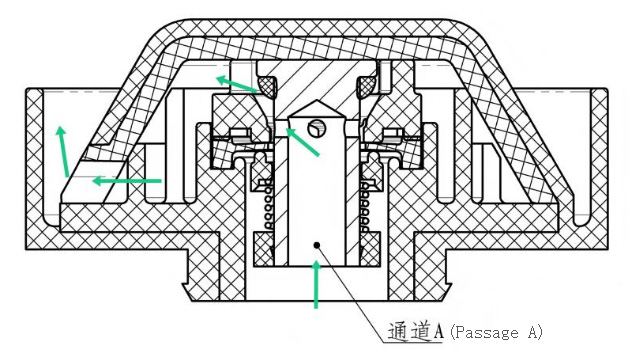

When the vehicle starts, operating the hand brake valve charges the parking chamber of the spring brake chamber. Compressed air enters the parking chamber and, through the action of the rubber diaphragm, compresses the parking spring, thereby releasing the vehicle’s parking brake. As the space containing the parking spring is compressed, the air that must be expelled pushes the valve core assembly to overcome the spring force of the valve spring (9), forming a passage between the valve core assembly and the valve seat (6). The air is then expelled to the outside (exhaust flow direction shown in Figure d).

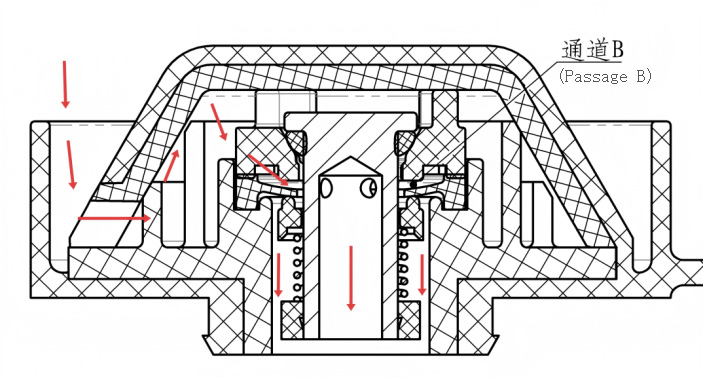

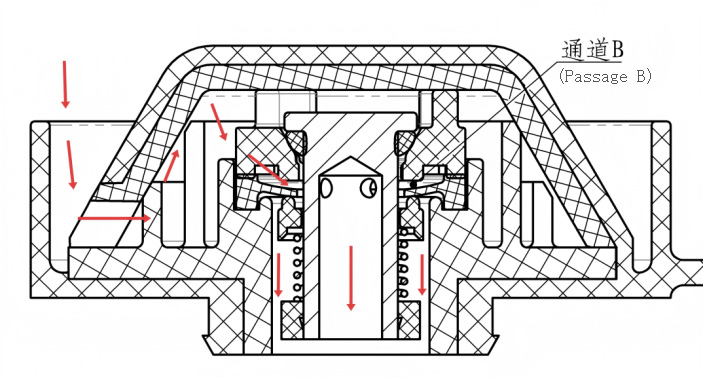

When the vehicle is parked, operating the hand brake valve vents the parking chamber of the spring brake chamber. The parking spring is released, and the spring release force is converted into parking braking force, achieving vehicle parking. As the parking spring expands, the increased space must draw in external air. External air enters through the breather port in the upper cap (2) and flows through the channel in the base (3), pushing the diaphragm (7) to overcome the spring force of the valve spring (9). This separates the diaphragm (7) from the valve seat (6), forming Passage B (see Figure e), through which external air is drawn into the space containing the parking spring (airflow direction shown in Figure e).

Figure (d) Exhaust demonstration diagram

Figure (e) Inhalation demonstration diagram

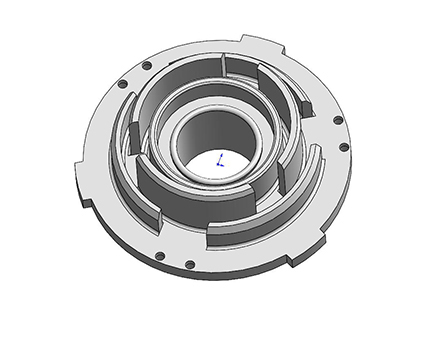

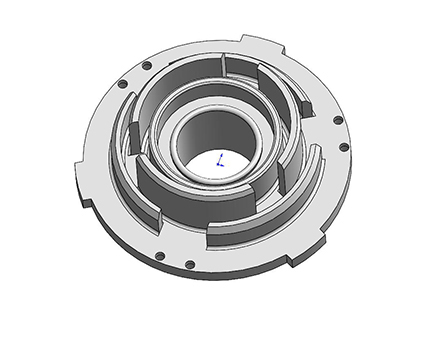

Figure (f) Base 3

Innovations

This design has the following innovative features:

Currently, no similar external internal breathing components are available on the market.

The external internal breathing component is highly versatile, easy to install, and compatible with existing drum-type dual-diaphragm spring brake chambers on the market.

The component is equipped with internal and external breathing channels, effectively preventing external contaminants and pollutants from entering, thereby maintaining a clean internal operating environment for the spring brake chamber.

The base (3) of the component is designed with multiple channels (see Figure f). During air intake and exhaust in the cavity containing the parking spring, these channels prevent external contaminants from being directly drawn into the component. Additionally, during exhaust, the design allows accumulated debris in the channels to be blown out to the exterior, significantly enhancing the operational stability of the component.

English

English Español

Español